Global-CE >

Station de mélange de sol stabilisée >

Roady Station de mélange de sol stabilisée >

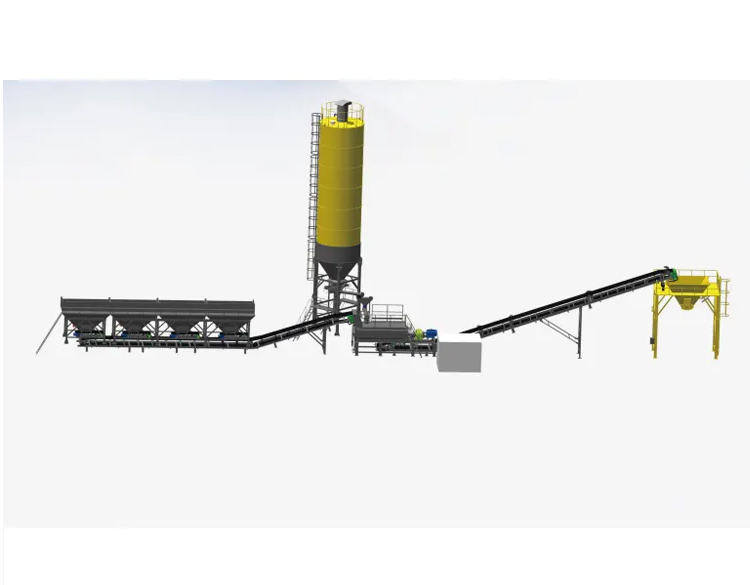

Roady WCBD300B Station de mélange de sol stabilisée

Roady WCBD300B Station de mélange de sol stabilisée

Caractéristiques du produit

1. Système d 'approvisionnement global

Aggregate feeders modularize unit design, fast and easy to installation; aggregate hopper outlet has material shortage alarm, fine aggregate hopper has material shortage alarm and also automatic vibration to ensure material flow smoothly; electronic belt can weigh continuously, motorfrequency conversion speed control, high measurement accuracy; practical belt with skirts edge to keep the data from sensors real and effective, and with higher measurement precision.

2. Système d 'approvisionnement de remplisseur

Vertical cement silo with pneumatic arch breaking; continuous level meter display in the control room; first transportation and then weighing, electronic spiral scales weighing system to achieve computer closed-loop control; powder stable flow silo to make the cement weighing more stable and reliable.

3. Système d 'approvisionnement en eau

Water tank level control automatically, water level max and min limit alarm, and interlock with the water supply pump; with frequency ration water supply system, with accurate water supply, energy save, reliable work.

4. Système de mélange

Double shaft batch typemix, mixing uniformity;none wear-proof plate technology reduces blade wear; mixer blade is made of special wear-resistant material, with long service life; discharge port with receiving hopper, feed inlet with cover, well-sealed fillerinlet makes the operation site clean and environmentally friendly.

5. Système de transport matériel de finition

Compact steep conveyor structure;segmented modular design, easy to disassembly and transport;with a variety of anti-bias measures

6. Silo de mélange fini

Pneumatic door mechanism, running smoothly, lower error rate;Optimization of storage capacity can not only meet the operating convenience, but also prevent segregation;warehouse wall vibrators prevent corner plot material in discharging

Système 7.Control

Container type control room, good insulation properties, beautiful appearance, good seal performance, easy and fast to installation and transportation; centralized control PLC, operation language can be customized, manual, semi-auto and fully auto control mode switch freely; one key to boot and shutdown, with error detection and alarm functions; with complete various parameters, real-time report and historical report are easy to print.

Aggregate feeders modularize unit design, fast and easy to installation; aggregate hopper outlet has material shortage alarm, fine aggregate hopper has material shortage alarm and also automatic vibration to ensure material flow smoothly; electronic belt can weigh continuously, motorfrequency conversion speed control, high measurement accuracy; practical belt with skirts edge to keep the data from sensors real and effective, and with higher measurement precision.

2. Système d 'approvisionnement de remplisseur

Vertical cement silo with pneumatic arch breaking; continuous level meter display in the control room; first transportation and then weighing, electronic spiral scales weighing system to achieve computer closed-loop control; powder stable flow silo to make the cement weighing more stable and reliable.

3. Système d 'approvisionnement en eau

Water tank level control automatically, water level max and min limit alarm, and interlock with the water supply pump; with frequency ration water supply system, with accurate water supply, energy save, reliable work.

4. Système de mélange

Double shaft batch typemix, mixing uniformity;none wear-proof plate technology reduces blade wear; mixer blade is made of special wear-resistant material, with long service life; discharge port with receiving hopper, feed inlet with cover, well-sealed fillerinlet makes the operation site clean and environmentally friendly.

5. Système de transport matériel de finition

Compact steep conveyor structure;segmented modular design, easy to disassembly and transport;with a variety of anti-bias measures

6. Silo de mélange fini

Pneumatic door mechanism, running smoothly, lower error rate;Optimization of storage capacity can not only meet the operating convenience, but also prevent segregation;warehouse wall vibrators prevent corner plot material in discharging

Système 7.Control

Container type control room, good insulation properties, beautiful appearance, good seal performance, easy and fast to installation and transportation; centralized control PLC, operation language can be customized, manual, semi-auto and fully auto control mode switch freely; one key to boot and shutdown, with error detection and alarm functions; with complete various parameters, real-time report and historical report are easy to print.

Paramètres du produit

| Spécification technique | Modèle : WCBD300B |

|---|---|

| Capacité évaluée | 300t / h |

| Quantité de trémie froide | 4 |

| Volume de trémie froide | 10m et sup3 ; |

| Capacité de stockage temporaire de poudre | 35m & sup3 ; |

| Puissance de l 'agitateur | 45kW |

| Capacité d 'entrepôt finie | 4,5 m et sup3 ; |

| Diamètre maximum d 'aggregrate de mélange | 45 millimètres |

| Méthode de pesage d 'agrégats | Courroie électronique |

| Méthode de pesage de poudre | Balance électronique en spirale |

| Méthode de pesage de l 'eau | Rapport de fréquence pour la mesure |

| La puissance totale installée | 93,7 kW |

| Les dimensions | 35m & fois ; 19m & fois ; 13m |